IEE S.A., a world leader in smart sensing solutions for automotive and other markets, is proud to announce that it has been awarded the prestigious FEDIL Innovation Award 2024 in the “Product” category. The award recognizes IEE’s groundbreaking innovation: the Laminated Busbar Connector for batteries of electric vehicles (EV) or energy storage facilities.

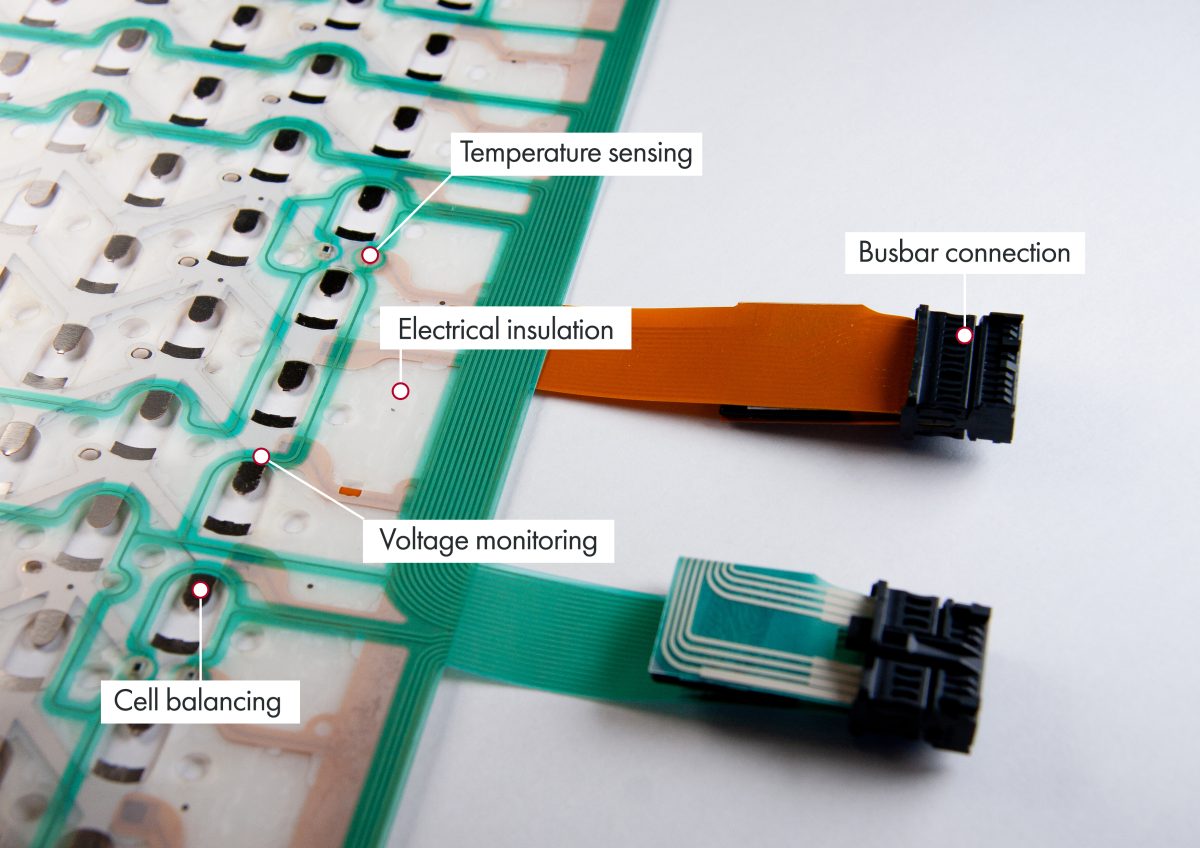

The Laminated Busbar Connector is a compact, lightweight hybrid solution combining printed electronics with traditional electronic assembly elements. This revolutionary product integrates multiple functionalities—such as voltage monitoring, cell balancing, temperature sensing, electrical isolation, and busbar connection—into a single component. The innovation simplifies battery design, increases automation in manufacturing, and reduces production costs, ultimately making electric vehicles more affordable and accessible to a broader audience.

“We are incredibly proud of this achievement and this award is a testament to the dedication, creativity, and teamwork that have driven the development of the Laminated Busbar Connector” said Michael Olk, Business Development Manager at IEE. “Our cross-functional teams in Luxembourg have worked tirelessly to create a product that pushes the boundaries of innovation. We are excited to continue collaborating with the automotive and energy industries on solutions that contribute to a more sustainable future.”

By reducing the need for traditional cabling, the Laminated Busbar Connector saves space within the battery pack, allowing more room for electricity charging cells, which in turn enhances the driving range of electric vehicles. Its customizable design also extends the benefits to energy storage and industrial battery systems, further contributing to a sustainable future.

“We are honored to receive the FEDIL Innovation Award 2024 in the Product category,” said Alain Schumacher, Chief Technology Officer of IEE. “This recognition highlights our commitment to developing cutting-edge solutions that do not only drive technological progress but also create tangible benefits for the environment and society. The Laminated Busbar Connector is just one example of how IEE is innovating to shape the future of electric mobility and energy storage.”

IEE continues to lead the charge in smart sensing technologies, pioneering solutions that support the global energy transition and a sustainable mobility.

We offer a complete range of sensing and heating solutions to improve the safety and durability of your battery safety pack.

Congratulations also to the other awarded companies:

Husky Technologies for its “Plate Line Automation” project (category: Process)

Creos Luxembourg S.A. / DataThings S.A for their project “Kopr: The AI Twin of the Smart Grid” (category: Data / AI)

CTI Systems S.à r.l. / Gradel S.à r.l. for their “On Board Cargo Loader” (category: Engineering Excellence)

IEE Hits Record Sales Turnover despite Challenging Times for the AutomotiveThanks to investment in R&D and manufacturing, as well as growing demand for vehicle interior sensing solutions, IEE S.A. maintains a profitable position on the market amidst global instability.

High energy prices, high inflation, high interest rates, geopolitical challenges, and economic recession – the overall climate has not been particularly favorable to the automotive industry. Nevertheless, IEE Group (which includes ALL Circuits, acquired in 2015, delivering electronics manufacturing services) has continued to grow its revenue significantly.

IEE Group managed to generate a total revenue of 682,4 million euros in 2023, an increase of 24,6% compared to 2022 (547,8 million Euros). EBITDA is at 64,5 million euros, which means a progress of 60,5% compared to 2022 (40,2 million Euros).

The main drivers behind IEE’s continuous growth are technologies such as hands on/off sensing (HOD) that support assisted and automated driving functionalities, novel vehicle safety features like Child Presence Detection (VitaSense), and the increasing fitment of seat belt reminder systems (SBR) to the rear seats of vehicles. Furthermore, our daughter company, ALL Circuits, has seen an increase in orders of electronics manufacturing services (EMS) for electric vehicles (inverters, battery management electronics) during the past year.

“We take pride in our in-house built sensors that make cars all over the world safer and enhance the driver and passenger experience. Innovation has always been at the heart of IEE’s strategy, and we continue to invest in vehicle interior sensing solutions to further improve occupant safety and comfort. We also support safe usage of assisted and automated driving systems,” says Paul Schockmel, CEO at IEE S.A.

For over three decades, IEE has gathered incomparable car seat and car interior know-how, with which it kept developing a wide variety of safety and comfort sensing solutions renowned worldwide. ALL Circuits ranks 45 among the global Top 50 EMS companies and is strongly benefitting from the vehicle electrification trends in Europe.

Over the past 5 years, IEE has invested an estimated 30 million euros in Luxembourg, where the headquarters are, in R&D and Manufacturing 4.0. Aside from investing into resources, building up and developing solutions for growing markets such as car electrification and automated driving, IEE looks into the future and develops innovative technologies and new applications also outside of the automotive industry, in eHealth, and Industry 4.0, for example.

IEE’s Management expects the company to be in the growth curve also this year with full order books. IEE Group booked new orders in 2023 which are worth more than 1500 million Euros. The Management is made up of Paul Schockmel (CEO), Kevin Hui (CFO), Alain Schumacher (CTO), Christophe Keiser (COO) and Bruno Racault (President at ALL Circuits).

What “Level” does your car have?A major trend in the automotive industry is to increasingly equip vehicles with technology that aims at making the driving more comfortable by supporting the driver.

When you read or watch information in public media related to vehicles assisting the driver in its driving task or even driving autonomously, you may notice statements like “the car has Level 2 capabilities” or “vehicle manufacturer xy plans to launch a Level 4 vehicle in 2030”. But what are these “Levels”, what do they mean?

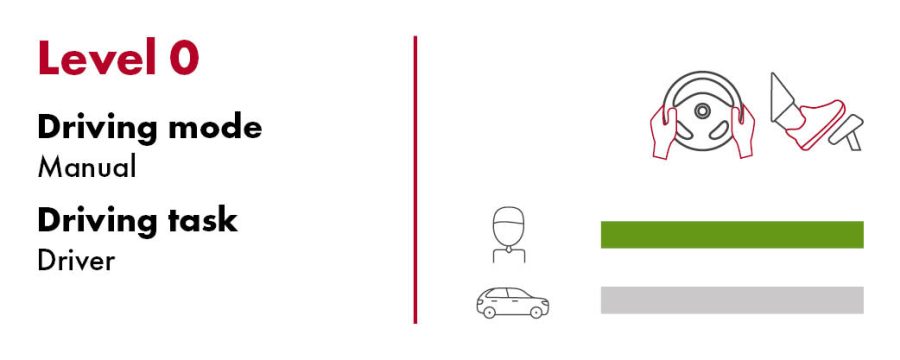

With increasing availability of driver assistance systems and following evolutions towards automated or even autonomous driving, the SAE (Society of Automotive Engineers) has “categorized” the systems, from Level 0 to Level 5. SAE J3016 defines the “Levels” depending on various key criteria: the capabilities of the vehicle, the role of the driver, and the variety of roads that the vehicle can handle.

Level 0: In a simple way one can describe it as “manual” driving: the driver has to steer, accelerate and slow down the car, there is no system that could support him in these tasks. A Level 0 car may be equipped with safety features that can warn the driver (collision warning or lane departure warning), or act in emergency situations (Autonomous Emergency Braking, Emergency Lane Keeping). Still the car remains on a “0” Level as these systems do NOT continuously support the driver, they are no “assistance” systems but “safety” systems.

Level 0: In a simple way one can describe it as “manual” driving: the driver has to steer, accelerate and slow down the car, there is no system that could support him in these tasks. A Level 0 car may be equipped with safety features that can warn the driver (collision warning or lane departure warning), or act in emergency situations (Autonomous Emergency Braking, Emergency Lane Keeping). Still the car remains on a “0” Level as these systems do NOT continuously support the driver, they are no “assistance” systems but “safety” systems.

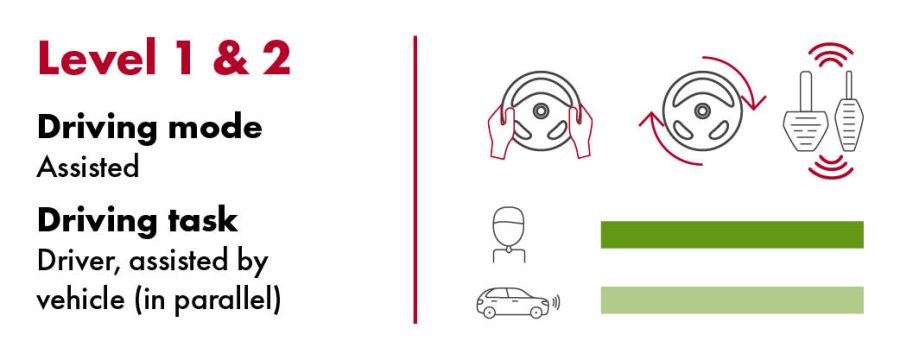

Level 1: The vehicle is equipped with a driver assistance system that can continuously support the driver in either lateral (steering) or longitudinal (braking, accelerating) control of the vehicle. Examples are Lane Keeping Assistance Systems or Lane Centring Systems (a camera detects the lane markings and the system continuously supports the driver to stay within the lane) or Adaptive Cruise Control (the distance to a preceding vehicle is measured, and the vehicle’s own speed can be adapted automatically to the speed of the preceding car).

Level 2: The vehicle can continuously support the driver in longitudinal and lateral control, it “combines” two Level 1 features. Such Level 2 systems can take over a significant share of the “driving task”, and with this comes a problem on how drivers perceive such systems. Many may get the impression, and some are even convinced, that their car is self-driving, and that they can disengage from the driving task – social media is full of such examples of driver overreliance. Still, such Level 2 systems are only “assistance” systems. The driver is solely responsible for the control of the vehicle, has the task to monitor the traffic situation and needs to intervene to avoid a crash, if necessary. A Level 2 system must typically be driven “hands on”, the driver is not allowed to remove the hands from the steering wheel.

Level 2: The vehicle can continuously support the driver in longitudinal and lateral control, it “combines” two Level 1 features. Such Level 2 systems can take over a significant share of the “driving task”, and with this comes a problem on how drivers perceive such systems. Many may get the impression, and some are even convinced, that their car is self-driving, and that they can disengage from the driving task – social media is full of such examples of driver overreliance. Still, such Level 2 systems are only “assistance” systems. The driver is solely responsible for the control of the vehicle, has the task to monitor the traffic situation and needs to intervene to avoid a crash, if necessary. A Level 2 system must typically be driven “hands on”, the driver is not allowed to remove the hands from the steering wheel.

The description “Level 2+” is often used for vehicles that allow the driver to remove the hands from the steering wheel on certain roads and under the condition that the driver keeps his eyes on the road and is ready to intervene immediately in case of a need. The driver is not allowed to engage in tasks that would distract his attention from the traffic situation. Such Level 2+ vehicles still fall under the SAE taxonomy of Level 2. For now, only a limited number of countries allow such systems on their roads.

The description “Level 2+” is often used for vehicles that allow the driver to remove the hands from the steering wheel on certain roads and under the condition that the driver keeps his eyes on the road and is ready to intervene immediately in case of a need. The driver is not allowed to engage in tasks that would distract his attention from the traffic situation. Such Level 2+ vehicles still fall under the SAE taxonomy of Level 2. For now, only a limited number of countries allow such systems on their roads.

What all the “Levels” described so far have in common is that the driver is always liable in case of an incident, is fully responsible for the operation of the vehicle, usage of the assistance systems and monitoring of the traffic environment.

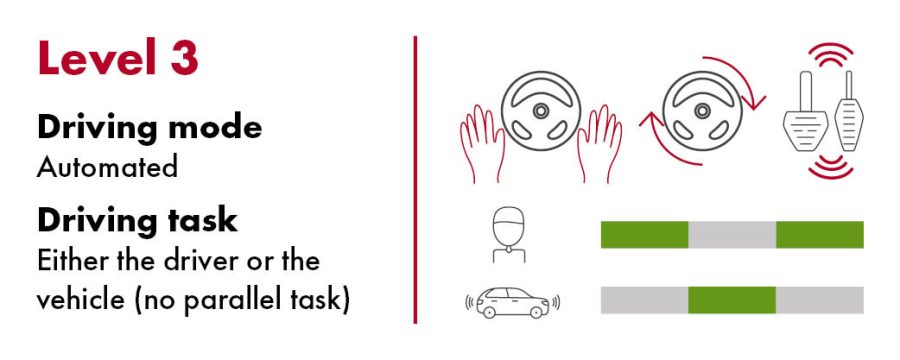

Level 3: Such a vehicle can be considered as a different “animal”, as now one moves from “assisted” driving into the world of “automated” driving. When the vehicle is capable to operate in Level 3 mode, the driver is allowed to disconnect from the driving task. He can be “hands off” and “eyes off” and engage in a secondary non-driving related task. However, the driver is not allowed to sleep or to leave the driver seat. He needs to remain available as a “fallback” to take back the driving control within a couple of seconds, if the vehicle requests him to do so. Under Level 3 operation the liability for incidents is with the vehicle, but as soon as the driver re-takes an active role in driving (e.g. steering), liability goes back to him. Hence it is crucial to precisely monitor who is in control of the vehicle (system or driver). Today a Level 3 operation of Automated Lane Keeping Systems, defined by UN regulation R157, is only allowed on highways! Beginning of 2022, the first R157 approved Level 3 vehicle entered the market and could be bought by end consumers.

Level 3: Such a vehicle can be considered as a different “animal”, as now one moves from “assisted” driving into the world of “automated” driving. When the vehicle is capable to operate in Level 3 mode, the driver is allowed to disconnect from the driving task. He can be “hands off” and “eyes off” and engage in a secondary non-driving related task. However, the driver is not allowed to sleep or to leave the driver seat. He needs to remain available as a “fallback” to take back the driving control within a couple of seconds, if the vehicle requests him to do so. Under Level 3 operation the liability for incidents is with the vehicle, but as soon as the driver re-takes an active role in driving (e.g. steering), liability goes back to him. Hence it is crucial to precisely monitor who is in control of the vehicle (system or driver). Today a Level 3 operation of Automated Lane Keeping Systems, defined by UN regulation R157, is only allowed on highways! Beginning of 2022, the first R157 approved Level 3 vehicle entered the market and could be bought by end consumers.

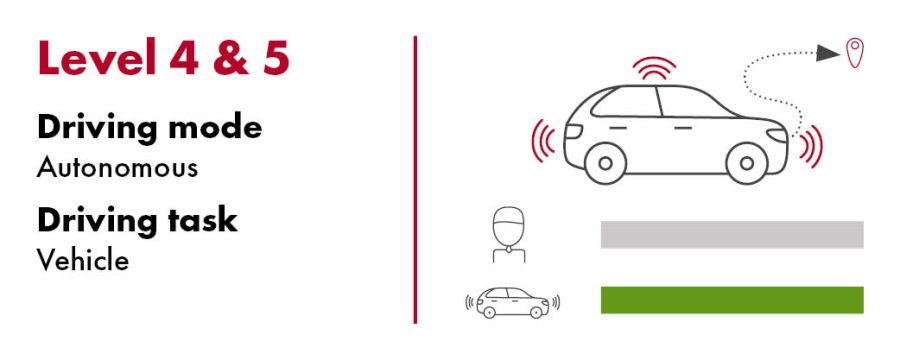

Level 4: With this next step one moves from “automated” to “autonomous” driving and a driver is potentially no longer needed. The driver can completely disconnect, sleep, or the vehicle might even be driverless. In case of an issue that does no longer allow a regular autonomous operation, the vehicle should bring itself into a safe situation. A limitation for Level 4 however is that such vehicles are not yet capable to ensure an autonomous operation on any kind of roads or under any driving/weather conditions. Level 4 vehicles are e.g. “roboshuttles” that operate in specific, well-defined areas. They typically run along a predefined route but cannot bring you to any destination of your choice. There are also “robotaxis” nowadays that have a broader flexibility in their operational environment, however, still with limitations. Level 4 vehicles may no longer have a steering wheel or pedals. No Level 4 passenger car is commercially available for end consumers at the moment, but some vehicle manufacturers are working on them.

Level 4: With this next step one moves from “automated” to “autonomous” driving and a driver is potentially no longer needed. The driver can completely disconnect, sleep, or the vehicle might even be driverless. In case of an issue that does no longer allow a regular autonomous operation, the vehicle should bring itself into a safe situation. A limitation for Level 4 however is that such vehicles are not yet capable to ensure an autonomous operation on any kind of roads or under any driving/weather conditions. Level 4 vehicles are e.g. “roboshuttles” that operate in specific, well-defined areas. They typically run along a predefined route but cannot bring you to any destination of your choice. There are also “robotaxis” nowadays that have a broader flexibility in their operational environment, however, still with limitations. Level 4 vehicles may no longer have a steering wheel or pedals. No Level 4 passenger car is commercially available for end consumers at the moment, but some vehicle manufacturers are working on them.

Level 5: This is the ultimate goal of fully autonomous driving. You can get into your vehicle, set a destination, and the vehicle will bring you there, no matter what kind of roads it needs to take, or what weather conditions. No further need for driver action, the car will do the job all alone until the end of the journey. Level 5 vehicles are a vision for the future, they do not exist today. They may be “pure” autonomous vehicles without any dedicated driver seat or driver controls, but they may also offer the full range of assistance or automation levels and the driver can chose whether he prefers to drive himself or to be driven.

IEE’s sensing solutions are a part of this assistance-automated-autonomous driving journey. Our Hands Off Detection (HOD) sensor is a crucial component to verify that the driver keeps his hands on the steering wheel when using a Lane Keeping Assist System (as Level 1 or Level 2 system), and it reliably monitors the transition between manual and automated driving for Level 3 vehicles. When owners of future Level 4 or 5 passenger cars are in the mood to drive themselves and use a lower Level mode, HOD will be there to verify their engagement in the driving task.

More on this topic: [SAE J3016, summarizing the key aspects of the different levels: SAE Levels of Driving Automation™ Refined for Clarity and International Audience]

The Seat Belt – An Underestimated Life Saving DeviceOver the last decades, vehicle safety never ceased to increase in importance, with practical improvements constantly being done to make the millions of cars in daily traffic a safe “hub” for drivers and passengers. Crash structures are made to absorb energy and the “safety cell” helps keep the passenger compartment intact. Seat belts and airbags mitigate injury risks by preventing the occupant to hit the vehicle interior or windshield, or to be thrown out of the vehicle.

The vehicles we drive today are truly designed and tested to meet a variety of safety standards. Still, it is also up to us, drivers, and passengers to make right use of the safety items which are fitted into a vehicle. Are we making the most of the safety tools at hand?

Let’s consider seatbelts for a moment. Wearing the seatbelt is still considered the most important factor in preventing serious or fatal occupant injuries in a vehicle crash. Seat belts have gone a long way since they were first introduced in 1959 as a standard equipment by Volvo. Initially just a rigid belt, many features have been added in the meantime to improve their wearing comfort as well as their safety performance. Widely unknown to the public, seat belt pretensioners and belt load limiters are key elements to further optimize the safety potential.

The pretensioner removes belt slack and allows for a belt interaction with the occupant to absorb energy already in an early phase of the crash. Belt safety is further supported by the load limiter, allowing for a controlled forward displacement of the occupant while limiting the force on the ribcage. A “rigid” seat belt has a higher risk of generating forces that could break the ribs, leading to potentially life-threatening injuries: The load limiters’ aim is to prevent this from happening.

NCAP (New Car Assessment Program) organizations worldwide assess vehicle safety, and their occupant safety requirements have managed to push the fitment of such advanced seat belt systems in vehicles – first for the front seats. By adding adult dummies on the rear seat in crash tests, Euro NCAP paved the way for these safety features to become available for all vehicle occupants. Pretensioners and load limiters are nowadays also installed on the rear seats of almost all new car models entering the European market.

However, even though your car may have the best seat belt system in the world, if you do not buckle up, you are putting yourself at high risks (one can be killed in a crash at speeds as low as 30 km/h)! A simple but effective function started to forge into the automotive world about 25 years ago: the Seat Belt Reminder (SBR).

Advanced SBR systems trigger an audio-visual signal, to remind the unbelted vehicle occupant to put their seat belt. On passenger seats, an occupant detection sensor checks whether the seat is occupied, and if the corresponding seat belt is not buckled, the reminder is activated. This SBR function has recently become a legal requirement for front row seats in many parts of the world.

In addition, almost every worldwide NCAP gives incentives if the same function is installed for the rear seats. Their key motivation: Rear seat passengers deserve the same level of protection as front seat occupants. Knowing that many people who typically buckle up on the front seats don’t do so when seated in the rear, it is even more important to have efficient SBR systems in the back of the car.

Unbelted rear occupants are not only exposed to serious hazard themselves. They are also a life-threatening danger for front seat occupants, who are twice as likely to be fatally injured if an adult occupant sitting behind them does not have the seat belt on.

Modern seat belt systems and advanced SBRs are a great combination to maximize the safety potential of the vehicle’s restraint system for any occupant. They have already saved many lives and will continue to do so.

At IEE, we are proud to continue to be a part of this evolving vehicle safety journey. Our SBR occupant detection sensors may be but a small, but highly relevant component in the overall function. Next time you drive, make sure your front and rear seat passengers are belted – unless the vehicle’s SBR system may have already taken care of it. Remember that the belt on the rear seat can also help save your life as a driver/ front seat occupant, not to mention that of your precious crew! Onward and upward.

Contributor: Thierry Mousel

Co-author: Silvia Martin

Unattended Child Detection – Pioneering a further vehicle safety functionA novel approach to address vehicular heat stroke fatalities

IEE has pioneered many vehicle interior sensing solutions that led to vehicle safety improvements. Almost 30 years ago, our success story started with the development of seat-based occupant detection sensors. A first application was to avoid deployment of the front passenger airbag if the seat was not occupied, while today occupant detection is mostly used in the context of seat belt reminder systems for front and rear seats. We were first-to-market with capacitive sensing for occupant classification, allowing for automatic deactivation of the airbag for child seats, and hands off detection in the steering wheel to support assisted and automated driving functions. And now we revolutionize vehicle safety sensing once more: unattended child detection by in-vehicle radar technology.

Unfortunately, a number of children die every year of heat stroke in vehicles because they have been left unattended. It happens worldwide, but only the United States have somewhat reliable databases tracking this kind of incidents. The large majority of the victims are less than 3 years old. There are multiple reasons why a child may be left behind in the vehicle, but the key issue is: on a sunny day the vehicle interior temperature can reach a critical level within 15 minutes, and the children can do nothing to rescue themselves. As vehicle interior sensing specialists, we took up the challenge some 10+ years ago to find a solution to detect these children. Frequently the victims are young infants, that often fall asleep in vehicles. So, the challenge was to find a solution capable to quickly detect sleeping infants and to enable the vehicle to trigger an alert while the caretaker is still in the vicinity of the car.

After having evaluated a number of sensing approaches, we identified radar technology as the ideal technology. In combination with a smart algorithm, the system can detect the minor motions of a sleeping infant. And should the child be protected from the sun by a child seat integrated sunshade, the radar signals simply “looks through” the sunshade, which an optical system would not be able to do. Same for a child that might hide under the seat of a school bus. A radar sensor also creates no potential privacy issues as it doesn’t generate a picture of the vehicle interior.

For the system and algorithm development we recorded data for numerous sleeping and moving children of different ages, with a focus however on infants, as they are the most critical to detect. But as children are not always available for testing or demonstration purposes, a test tool was needed. As no suitable device was commercially available, we ran a project to develop an in-house test tool that was capable to mimic the breathing motion of a sleeping infant. This “breathing dummy” called Vivian has become a key element of our development.

Based on our radar technology, we have developed two different systems:

- VitaSense for passenger cars

- LiDAS for school buses

The VitaSense sensor module is integrated invisibly behind the headliner by the vehicle manufacturer, and the warning strategy (flashing lights, vehicle horn, smartphone message, etc) depends on the vehicle’s capabilities. VitaSense has entered the automotive market in December 2020 and is a finalist of this year’s Automotive News PACE award.

LiDAS (Life Detection Assistance System) can be integrated as an aftermarket solution into existing school bus fleets. LiDAS is made up of an array of radar sensors to cover the whole bus interior. It comes with a Central Control Unit, a wireless communication modem and a cloud-based data management hub, to trigger warnings and to interact with driver and fleet operator. Pilot trials with school districts started back in 2019, and market launch of LiDAS took place in 2020.

There is an increasing awareness of vehicle safety stakeholders and regulatory authorities for the issue of vehicular heat stroke. Euro NCAP has decided to introduce incentives for “Child Presence Detection” into its rating scheme starting 2023. They also have validated our test tool “Vivian”, so it can be used for the Euro NCAP assessment of VitaSense-equipped vehicles. In the United States, the recently adopted “Infrastructure bill” includes provisions to address the risk of leaving a child or unattended passenger in a vehicle.

Technology can be a key part of the solution if children are at risk because of memory failures, distraction or misunderstandings of the caretakers – humans are not perfect and will never be. We are confident that VitaSense and LiDAS will play an important role in reducing the number vehicular heat stroke incidents and help to save lives.

HOD in the SpotlightHow hands on/off detection helps comply with assisted/automated driving system regulations

ADAS – friend or foe?

The United Nations have initiated a couple of vehicle regulation activities related to assisted and automated driving systems in recent years. Two items were of key concern: ensure that the systems are safe AND that they are used in a safe way. Special focus was given to the role of the driver when using such systems.

Advanced Driver Assistance Systems (ADAS) hold undeniably numerous advantages, but there is also a risk they might be misused, depending on how their Human-Machine-Interface is implemented and the driver’s behaviour. The social media abound of videos in which drivers take their hands off the steering wheel, execute side tasks, or even leave the driver seat as if their cars were self-driving and fully autonomous. Those vehicles, however, are only equipped with driver assistance systems (often referred to as “Level 2” systems) that require the driver to keep the hands on the steering wheel and to actively be engaged in the traffic. Drivers misusing their ADAS are a known issue, and the consequences can be dire. Crashes investigated by NTSB (National Transportation Safety Board) in the United States clearly confirm that the lack of driver engagement played a key role.

Automated systems – Where clear communication interface is vital

When it comes to vehicles with automated driving capabilities (“Level 3”), the challenge is to make sure the driver understands which driving mode the vehicle is in: is the driver or the vehicle in control of the driving task? Also, how to ensure a safe transition between the driving modes? The “role change” involved when switching from automated to manual (or assisted) mode is critical for safety reasons: The task to monitor the traffic environment goes from the vehicle back to the driver. Therefore, before the control is returned to the driver, it must be clear to both driver and vehicle that it is the driver who is “back in the loop” This is also important from a liability point of view in case it is the vehicle that causes the crash: was the vehicle responsible (Level 3), or the driver (Level 2)?

Evolving technologies & safe drive – A regulatory affair

Two key regulations have been adopted to address the challenges mentioned above.

The UN Regulation 79 refers to Lane Keeping Assist Systems and includes a “hands off” detection requirement. If the driver removes hands from the steering wheel, an optical warning must be triggered after maximum 15 seconds, enhanced by further escalations such as acoustic warnings latest after 30 seconds. Should the driver still not grab the steering wheel, an emergency signal is triggered after 60 seconds and the lane keeping function is deactivated. New vehicle models on the European market with a Lane Keeping Assist System must comply with this hands-off detection requirement since April 2018.

Vehicles with automated driving capabilities entering the market these days legally allow the driver to take the hands off the steering wheel and the eyes off the road under certain conditions: On the highway only, with a maximum operational speed of 60 km/h. Such vehicles will have to comply to the UN Regulation 157 on Automated Lane Keeping Systems (ALKS), applicable since January 2021. The regulation mandates a “driver availability” function checking whether the driver is present in the driver seat and not sleeping. This is imperative to ensure that the driver is quickly available in case the vehicle would initiate a transition demand asking the driver to take back the control. On top, a full transition from automated back to manual driving requires a confirmation that the driver holds the steering wheel and that the eyes are directed on the road. If the confirmation does not take place, the vehicle would have to execute a minimum risk manoeuvre, ultimately bringing the vehicle to a halt.

HOD – The solution for a safe and smooth driving transition

Fast and reliable hands on/hands off detection can be ensured with our capacitive HOD sensor that entered that market already in 2013, as our lead customer recognized early on the need for securing driver engagement, long before any regulatory requirement. HOD, our in-house made sensing technology built on extensive expertise and quality checks, won the prestigious PACE award in 2018 – a sort of “Oscar” equivalent in the automotive supplier world.

The initial sensor was designed to identify the hands on/off status. Since then, we have constantly researched and upgraded it, so that today we bring its performance to the next level. Our latest multizone sensor is now capable to also classify the degree of driver control. Thus, it indicates whether the driver merely touches the steering wheel or whether he/she firmly grabs it. This brings a better view on how safely a driver is in control of the steering wheel.

In such sensitive and safety-critical situations as a driving mode change towards the driver, it is imperative to distinguish whether the driver has a safe grip of the steering. HOD therefore plays a key role in advanced driving functionalities and supports vehicle manufacturers in being compliant with the regulatory demands supporting safe driving as we evolve into the future.

From Start-Up to Global Player with Printed ElectronicsNot many people can speak with more passion and enthusiasm about printed electronics within IEE than Dr. Alain Schumacher. Which is no wonder, considering he has been active in the “field” for his entire career and knows the topic inside and out. Here is a short interview that sheds some light on the lesser publicized universe of printed electronics, widely integrated into IEE’s mainstream business, from the past and into the future.

IEE and Printed Electronics, how does that connect?

Starting out as a small company with a moderate presence in the industrial and medical markets, IEE decided to propose the potential of printed electronics to the automotive sector back in the days. This had a direct, significant impact on the evolution of our value chain. IEE experienced different challenges, decisions, and market circumstances which lead us to our present business model, mostly based on printed electronic devices. Printed electronics products are still at the very heart of the IEE business, 30 years down the road.

How have printed electronics built on IEE’s success over the years?

Initially a three-man crew, IEE S.A. is today a global market player with more than 2000 employees working in R&D and the production of sensing technologies. Our flexible printed electronics products integrate various market segments with a strong focus on systems designed for automotive interior comfort and safety applications. This is one of the most demanding sectors in terms of liability, technical and economical requirements, and a rather hostile environment for polymer-based electronic systems.

The development of sensor mats based on a similar principle as membrane switches but with improved reliability and performance were the entrance ticket to the global automotive market. Integrated in the car seat for Passenger Presence Detection (PPD) functionality, the systems enabled to better control the airbag firing, thus, to making passengers’ lives safer and reducing airbag repair costs. Since then, our sensor variants for additional applications have equipped no less than 400 million cars.

In time, the advantage of the favorable aspect ratio of thin flexible films combined with the high design freedom of printed electronics technology became obvious and opened the door for further sophisticated applications related to automotive safety and comfort (hands off detection for steering wheels) but also medical applications (footwear sensing solutions that help prevent Alzheimer’s’ and monitor health and sport performance).

What are the unique advantages of using printed electronics from IEE?

Obviously, our technology is much more than merely producing foil sensors. What truly makes us stand out and is our unique offer to customers for their various applications, which we prepare completely in-house, from A to Z. We first research a solution, develop it, put it on the production line, thoroughly check the quality of the end product, test it and when it is approved by our teams, it is ready to go to the customer and we start the mass production. We call this comprehensive service based on our extensive competences in material sciences, design, hardware and software development, manufacturing, quality, etc. “from lab to fab”.

What does it take for a company with roots in printed electronics to go towards IoT?

Identifying the potential of key technologies is the essential starting point to developing specific business ideas. But agility, innovative spirit, strong interdisciplinary and strategic partnerships as well as state-of-the-art customer intelligence, know-how and timely favorable market conditions are also mandatory prerequisites for a successful, sustainable, and prosperous evolution of any project.

Also, to maintain a competitive position in continuously challenging and changing market environments, the vision must be focused on how to satisfy the demand and potential functions best, rather than to hold on to traditional technologies. Thus, driving the establishment of high-level R&D infrastructures for more complex systems is required and competencies in disciplines like digitalization, big data, cyber security up to functional safety are being integrated into the making of future products. We know that printed/hybrid electronics technologies have great potential for future automotive and consumer applications. We are on the way to extending our market position via implementations of new technologies.

Alain Schumacher is Chief Technology Officer at IEE and acts as Vice-Chair Europe within the Board of Directors for OE-A (Organic and Printed Electronics Association)

New CEO for IEEPress release, 23rd March 2021

On Friday, 18th March 2021, Mr. Michel Witte, CEO and President at IEE officially stepped down from his position and left the task to steer the company to Mr. Paul Schockmel, former Vice President Strategy, Innovation and Marketing.

As the founder of the company, Mr. Witte has been an instrumental figure in IEE’s history, driving the company from a small Luxembourgish start-up to a global business success, making it a reputed, essential player in the automotive sensing industry. Over the past 30 years, IEE pioneered occupant detection, capacitive sensing in vehicle interior with products such as BodySense and Hands Off Detection (HOD), witnessed a large scale industrialization of printed electronics, and released VitaSense Child Presence Detection as another world premiere, among others, under his leadership.

The new CEO is Mr. Paul Schockmel, who will also exercise the functions of Director of the Board, and Member of the Executive Committee of the IEE Group.

Since joining IEE S.A. in 1995 as a Sales Engineer, Mr. Schockmel has held many key positions. Paul Schockmel also acted as the CEO of the European Association of Automotive Suppliers (CLEPA), developing a strong international network throughout the automotive industry. He also founded the Luxembourgish Association of Automotive Suppliers (ILEA) and co-founded the Luxembourg Automotive Components cluster.

“We welcome Mr. Schockmel in his new position and responsibility, and we will do everything necessary to support him in achieving his goals for the company,” says Sheng Wang, Chairman of the Board of Directors at IEE. “We trust that Mr. Schockmel has all the abilities to successfully lead the management team and the entire IEE staff throughout current and upcoming market challenges, and to make the company fit for the future.”

The entire staff at IEE is grateful to Mr. Michel Witte for his commitment and outstanding lifetime achievements within the company and wishes him all the best in his future endeavors. As a sign of respect and recognition, IEE’s Shareholders and the Board gave Mr. Witte the title of Honorary President of the IEE Group.

All IEE embraces the decision to have Mr. Schockmel at the head of the company and is looking forward to more exciting opportunities and adventures ahead under his guidance.

Our VitaSense Child Presence Detection hits the automotive marketPress release, 19th January 2021

We’ve been pioneering the in-cabin automotive sensing solutions industry for almost 30 years, focusing on occupant detection and classification to enhance passenger safety. Today, IEE is ready to address Child Presence Detection and releases VitaSense, a highly accurate radar sensor system capable of detecting the vital signs of a new-born baby and help prevent tragic hot car deaths.

“VitaSense is the world’s first interior radar sensing solution for Unattended Child Detection (UCD) in vehicles and is likely to become a landmark product for our company,” says Alain Schumacher, Chief Technology Officer at IEE. “Firstly, we identified the problem of children left unattended in vehicles, exposed to heatstroke risk. In the United States alone, 39 children die of vehicular heatstroke on average each year. With our experience in intelligent sensor solutions, we were eager to develop a product capable to “spot” these children, who are frequently sleeping infants, to enable the triggering of saving measures.

We have conducted extensive research and tests together with universities and medical specialists. We monitored, analyzed and simulated a wealth of data coming from real-life breathing patterns, from new-born babies to adults. Thanks to our know-how, VitaSense has the necessary capabilities to detect children, even when they sleep, and when they lie beneath a blanket. We are very proud of our field work that helped us develop a high-accuracy, reliable sensor which contributes to saving lives.”

VitaSense is a small sensing unit that can easily be integrated behind the vehicle’s headliner without altering the interior design. When an unattended child is detected, the vehicle’s alarm and communications systems can alert caretakers or passers-by that a child is still present in the car. Various warnings can be triggered depending on the vehicle’s capabilities: flashing lights, sounds, smart phone messages, etc. As it is based on radar technology, VitaSense is fully respecting your privacy, as no camera is used.

What makes VitaSense a ground-breaking, one-of-a-kind product is its unique mix of advanced sensing technology with innovative algorithms, in combination with easy implementation for the vehicle manufacturer. Fatal in-vehicle heatstroke accidents involving children is a global issue which has lately been receiving increasing attention.

“With Euro NCAP incentives starting 2023 as well as the US Hot Cars Act on the political agenda, aiming at heatstroke prevention for Unattended Children, we know that VitaSense can become a product of choice for the world’s vehicle manufacturers. This is IEE’s first radar product which is part of a family of future applications,” says Alexander Treis, Business Development Manager at IEE.

VitaSense is currently in mass production and the Genesis GV70 is the first vehicle equipped with this novel sensing solution as an option. Genesis is a premium brand of the Hyundai Motor Group.

Need a customized solution?

If you want to talk about customization options, price, availability or other related to this product