IEE S.A., a world leader in smart sensing solutions for automotive and other markets, is proud to announce that it has been awarded the prestigious FEDIL Innovation Award 2024 in the “Product” category. The award recognizes IEE’s groundbreaking innovation: the Laminated Busbar Connector for batteries of electric vehicles (EV) or energy storage facilities.

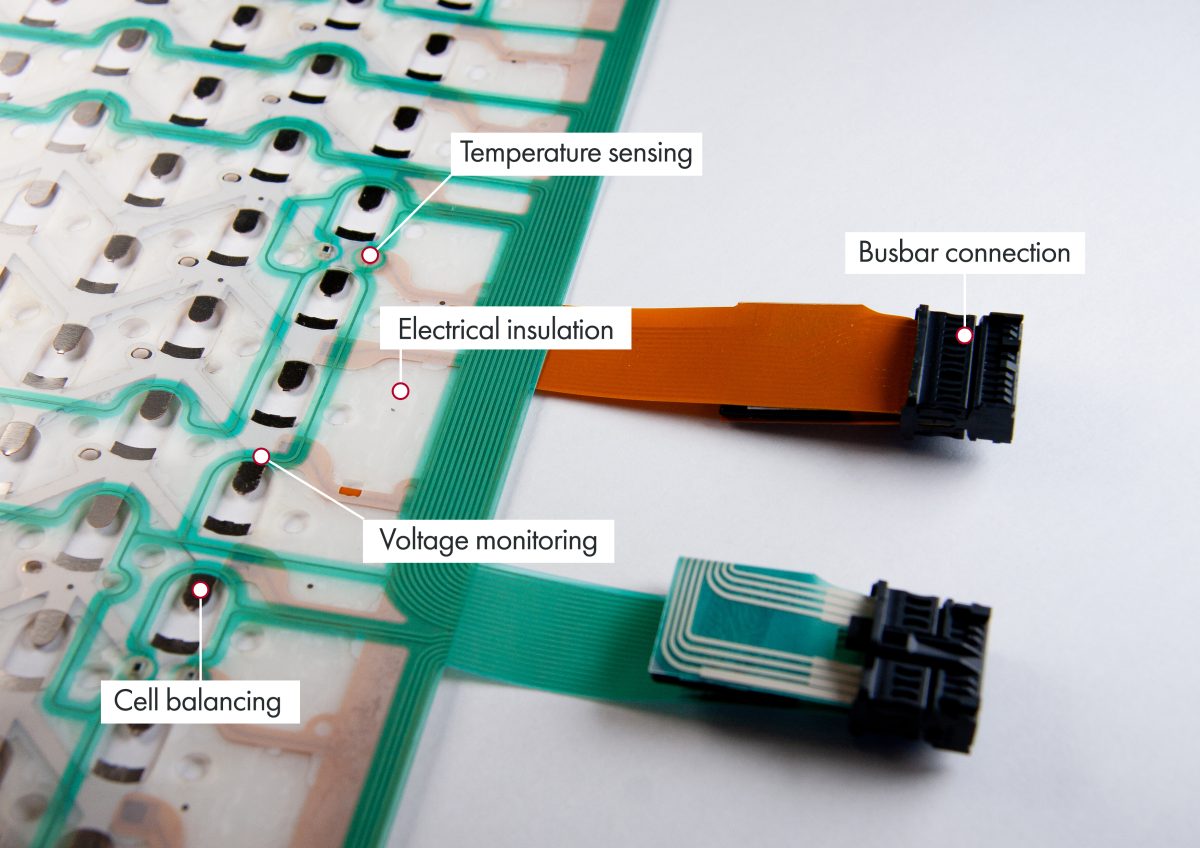

The Laminated Busbar Connector is a compact, lightweight hybrid solution combining printed electronics with traditional electronic assembly elements. This revolutionary product integrates multiple functionalities—such as voltage monitoring, cell balancing, temperature sensing, electrical isolation, and busbar connection—into a single component. The innovation simplifies battery design, increases automation in manufacturing, and reduces production costs, ultimately making electric vehicles more affordable and accessible to a broader audience.

“We are incredibly proud of this achievement and this award is a testament to the dedication, creativity, and teamwork that have driven the development of the Laminated Busbar Connector” said Michael Olk, Business Development Manager at IEE. “Our cross-functional teams in Luxembourg have worked tirelessly to create a product that pushes the boundaries of innovation. We are excited to continue collaborating with the automotive and energy industries on solutions that contribute to a more sustainable future.”

By reducing the need for traditional cabling, the Laminated Busbar Connector saves space within the battery pack, allowing more room for electricity charging cells, which in turn enhances the driving range of electric vehicles. Its customizable design also extends the benefits to energy storage and industrial battery systems, further contributing to a sustainable future.

“We are honored to receive the FEDIL Innovation Award 2024 in the Product category,” said Alain Schumacher, Chief Technology Officer of IEE. “This recognition highlights our commitment to developing cutting-edge solutions that do not only drive technological progress but also create tangible benefits for the environment and society. The Laminated Busbar Connector is just one example of how IEE is innovating to shape the future of electric mobility and energy storage.”

IEE continues to lead the charge in smart sensing technologies, pioneering solutions that support the global energy transition and a sustainable mobility.

We offer a complete range of sensing and heating solutions to improve the safety and durability of your battery safety pack.

Congratulations also to the other awarded companies:

Husky Technologies for its “Plate Line Automation” project (category: Process)

Creos Luxembourg S.A. / DataThings S.A for their project “Kopr: The AI Twin of the Smart Grid” (category: Data / AI)

CTI Systems S.à r.l. / Gradel S.à r.l. for their “On Board Cargo Loader” (category: Engineering Excellence)

The “feeling prosthesis” – Winner of the OE-A competition 2022LOPEC, translating into Large-area, Organic & Printed Electronics Convention is the leading international event for printed electronics. We have made a habit of not only attending it, but also participating in the OE-A competition (which is hosted within the frame of the event) -LOPEC is organized jointly by the OE-A (Organic and Printed Electronics Association, of which we are regular members) and Messe München GmbH.

This is where great minds in the world of printed electronics come together and, to everyone’s satisfaction and relief, this year, also face-to-face again. And this year again, our competition demonstrator seduced the jury, and we left the venue as winners in the category Best Prototype/New Product.

What about the demonstrator?

The winning demonstrator that we presented together with and thanks to one of our closest customers, Saphenus Medical Technology, is a feeling prosthesis, helping amputees “feel” the ground. That’s right: Suralis, as it is called, disposes of a unique, truly ground-breaking technology including sensors which improves the lives of those who lost their limb(s) by giving them back the sensation in a similar way a “real” leg does. Our smart footwear sensor transmits ground contact information to vibrators stimulating nerves in the upper leg. This means increased walking stability, confidence, and comfort, as well as reduced risk of phantom pain, of which most amputees suffer.

“For a medical product, it is very important to have a high-quality standard, not least because it must comply with various regulations,” says Rainer Schultheis, CEO at Saphenus. “Helping patients with phantom pain was our main motivator and we partnered with the right people who contributed to delivering this world-class technology.”

Why LOPEC?

Alain Schumacher, our CTO, who is also Vice Chair Europe within the Board of OE-A, appreciated that LOPEC is “the place to be for everyone who has a name in the printed electronics world, be it developer, organization, start-up, research institution, industrial. It is amazing what one can do for people by combining sensors with advanced medical technology. We have always been at the crossroads of various industries, supporting universities and customers with a fully customized service, from idea to mass production, going through solid research. This is how outstanding products such as “Suralis” come to life.

Our company won OE-A’s recognition in the same category for the ActiSense Smart Footwear System in 2020.

From Start-Up to Global Player with Printed Electronics

Not many people can speak with more passion and enthusiasm about printed electronics within IEE than Dr. Alain Schumacher. Which is no wonder, considering he has been active in the “field” for his entire career and knows the topic inside and out. Here is a short interview that sheds some light on the lesser publicized universe of printed electronics, widely integrated into IEE’s mainstream business, from the past and into the future.

IEE and Printed Electronics, how does that connect?

Starting out as a small company with a moderate presence in the industrial and medical markets, IEE decided to propose the potential of printed electronics to the automotive sector back in the days. This had a direct, significant impact on the evolution of our value chain. IEE experienced different challenges, decisions, and market circumstances which lead us to our present business model, mostly based on printed electronic devices. Printed electronics products are still at the very heart of the IEE business, 30 years down the road.

How have printed electronics built on IEE’s success over the years?

Initially a three-man crew, IEE S.A. is today a global market player with more than 2000 employees working in R&D and the production of sensing technologies. Our flexible printed electronics products integrate various market segments with a strong focus on systems designed for automotive interior comfort and safety applications. This is one of the most demanding sectors in terms of liability, technical and economical requirements, and a rather hostile environment for polymer-based electronic systems.

The development of sensor mats based on a similar principle as membrane switches but with improved reliability and performance were the entrance ticket to the global automotive market. Integrated in the car seat for Passenger Presence Detection (PPD) functionality, the systems enabled to better control the airbag firing, thus, to making passengers’ lives safer and reducing airbag repair costs. Since then, our sensor variants for additional applications have equipped no less than 400 million cars.

In time, the advantage of the favorable aspect ratio of thin flexible films combined with the high design freedom of printed electronics technology became obvious and opened the door for further sophisticated applications related to automotive safety and comfort (hands off detection for steering wheels) but also medical applications (footwear sensing solutions that help prevent Alzheimer’s’ and monitor health and sport performance).

What are the unique advantages of using printed electronics from IEE?

Obviously, our technology is much more than merely producing foil sensors. What truly makes us stand out and is our unique offer to customers for their various applications, which we prepare completely in-house, from A to Z. We first research a solution, develop it, put it on the production line, thoroughly check the quality of the end product, test it and when it is approved by our teams, it is ready to go to the customer and we start the mass production. We call this comprehensive service based on our extensive competences in material sciences, design, hardware and software development, manufacturing, quality, etc. “from lab to fab”.

What does it take for a company with roots in printed electronics to go towards IoT?

Identifying the potential of key technologies is the essential starting point to developing specific business ideas. But agility, innovative spirit, strong interdisciplinary and strategic partnerships as well as state-of-the-art customer intelligence, know-how and timely favorable market conditions are also mandatory prerequisites for a successful, sustainable, and prosperous evolution of any project.

Also, to maintain a competitive position in continuously challenging and changing market environments, the vision must be focused on how to satisfy the demand and potential functions best, rather than to hold on to traditional technologies. Thus, driving the establishment of high-level R&D infrastructures for more complex systems is required and competencies in disciplines like digitalization, big data, cyber security up to functional safety are being integrated into the making of future products. We know that printed/hybrid electronics technologies have great potential for future automotive and consumer applications. We are on the way to extending our market position via implementations of new technologies.

Alain Schumacher is Chief Technology Officer at IEE and acts as Vice-Chair Europe within the Board of Directors for OE-A (Organic and Printed Electronics Association)

Smart Sensors for Advanced Footwear Tech @MEDICA 2019For over 30 years, IEE S.A. has built itself a worldwide reputation for delivering exceptional sensing solutions predominantly for automotive interiors that help enhance comfort, safety and offer a better driving experience. Since its early days, however, IEE has also actively explored further possibilities to introduce its in-house, high-quality sensors to a wider range of applications, industries and markets that go beyond the automotive world and continues to do so.

For novel applications in the medical field, for instance, IEE has developed sensors that integrate digital shoes to support diabetic patients in monitoring their health status and prevent further foot damage. The first prototype of such a unique shoe will be exhibited at the MEDICA 2019 fair taking place in Düsseldorf between 18th-21st November. Visitors to the IEE booth will be able to try several applications that the shoe responds to and find out more about how it can be customized to accommodate various needs.

“This is not new ground for us,” says Tobias Meyer, System Engineer for Footwear and CIS Solutions at IEE. “We have been investigating into the possibilities of bringing to market a product that is more than a simple shoe insole sensor. We have created a complete solution instead, combining not only our experience in sensing technology, but also electronics, mobile apps and cloud services. Our customers can use this ready-to-go “package” and adapt it to their various specific needs, which allows them to be flexible in their applications.”

The footwear sensing solutions from IEE have been designed to provide easy, durable and comfortable integration into wearables that best address people with health difficulties such as diabetes, obesity, Alzheimer’s, etc. but also health professionals or sports people looking to improve or monitor their performance.

“These new solutions from IEE that support current and future healthcare technologies mark our intention to explore new business horizons and transit from printed electronics to IoT and Infonomics. It is the beginning of a journey we hope to continue,” says Meyer.

To discover more about our product’s capabilities and how they can apply to various specific needs, visit us at MEDICA 2019, Hall 3, Booth A74. Our specialists will be happy to walk you through all the possibilities.

Need a customized solution?

If you want to talk about customization options, price, availability or other related to this product